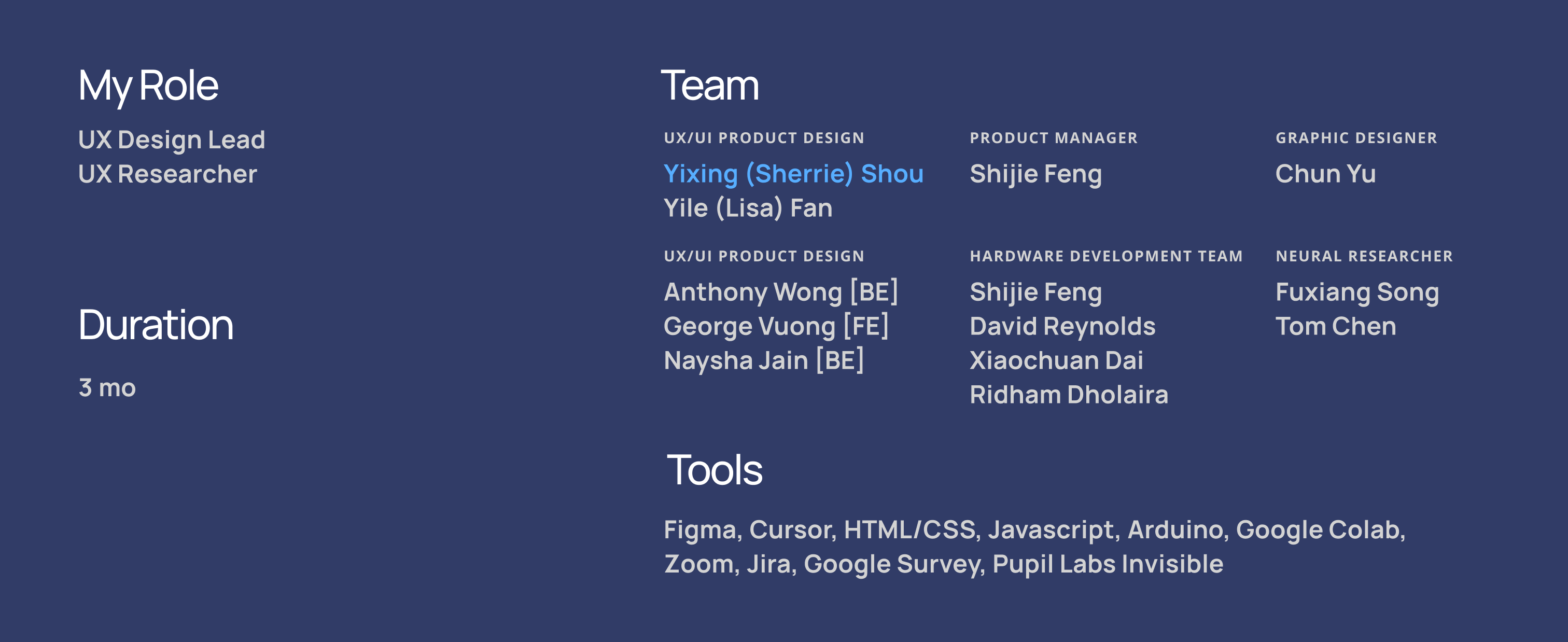

Project Goal

Design a guided, novice-friendly implantation interface that enables researchers to perform complex mouse brain neural implantation with greater confidence, consistency, and precision.

Confidential — Protected under NDA. Please do not screenshot, record, or distribute this material.

Who is Our Partner?

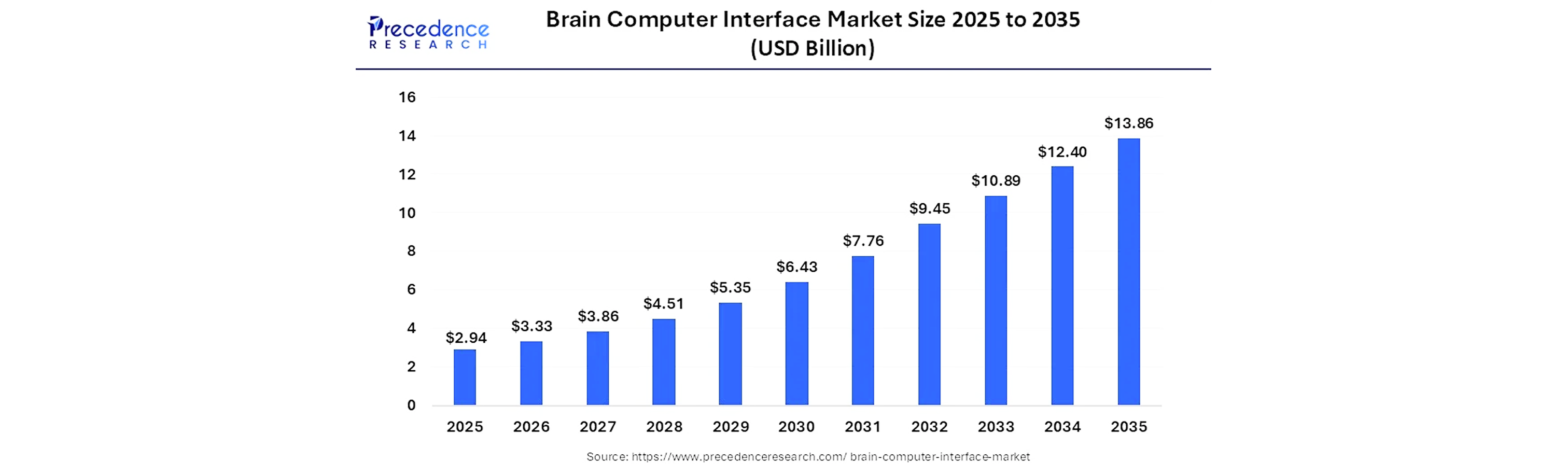

< ---------- > (Protected) is a neurotech company based in Cambridge, MA building next-generation brain–computer interfaces (BCIs) that aims at enabling seamless brain–computer communication.

As < ---------- > (Protected) expands its technology beyond expert users, the usability of its implantation system becomes a key driver of adoption and scalability.

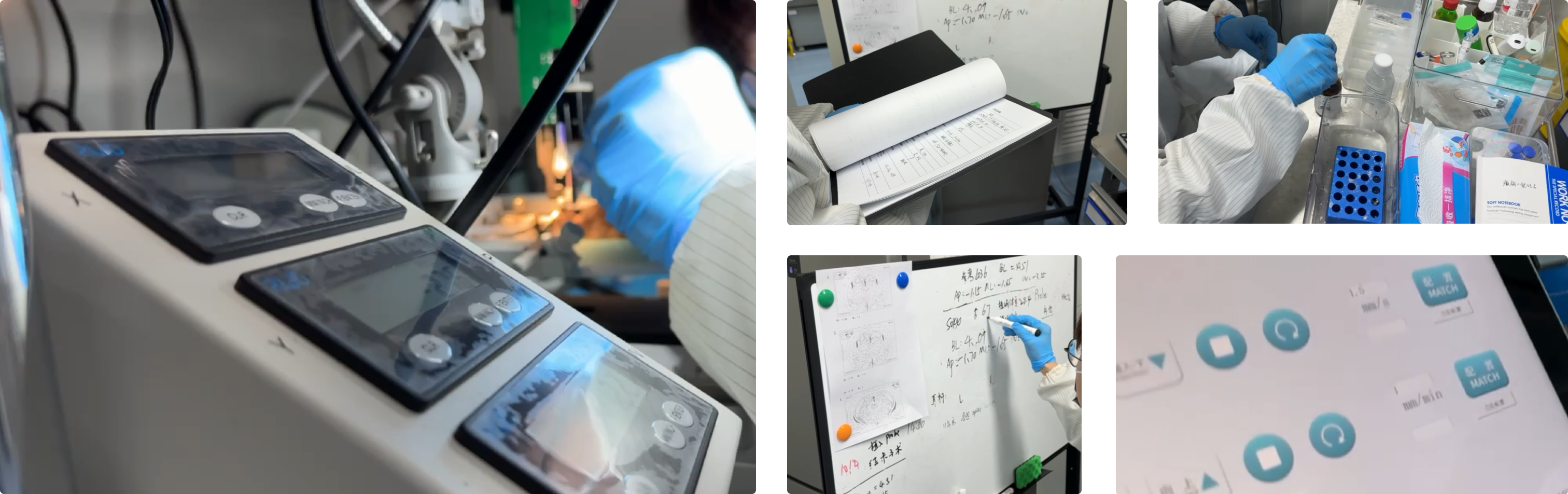

Field Research

![]()

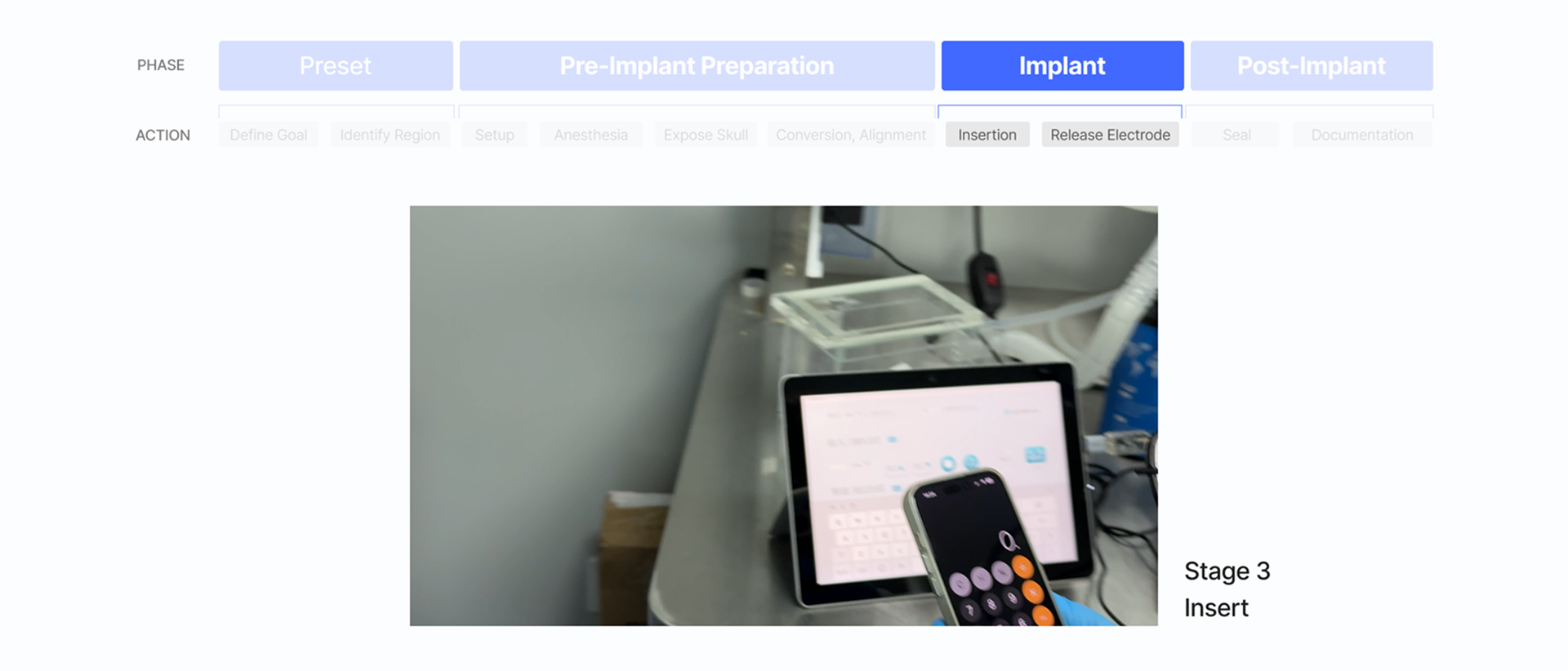

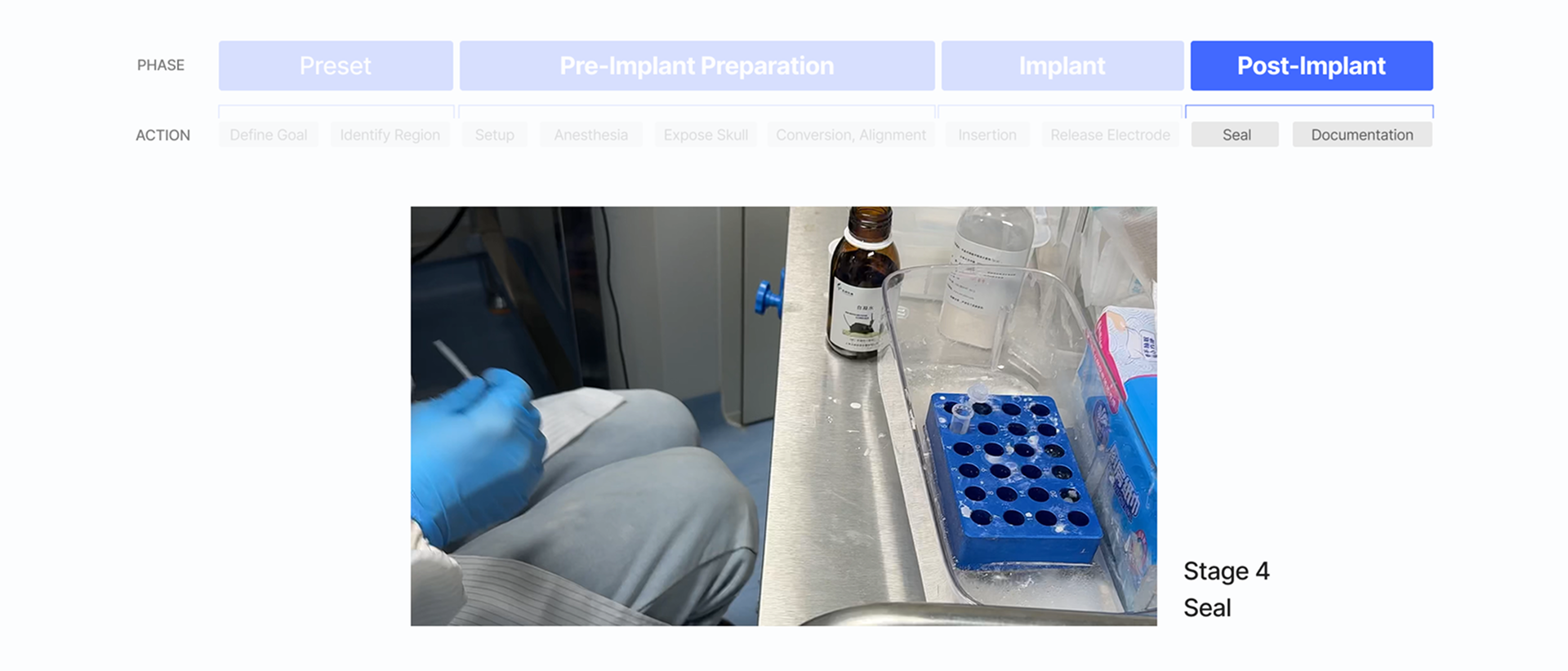

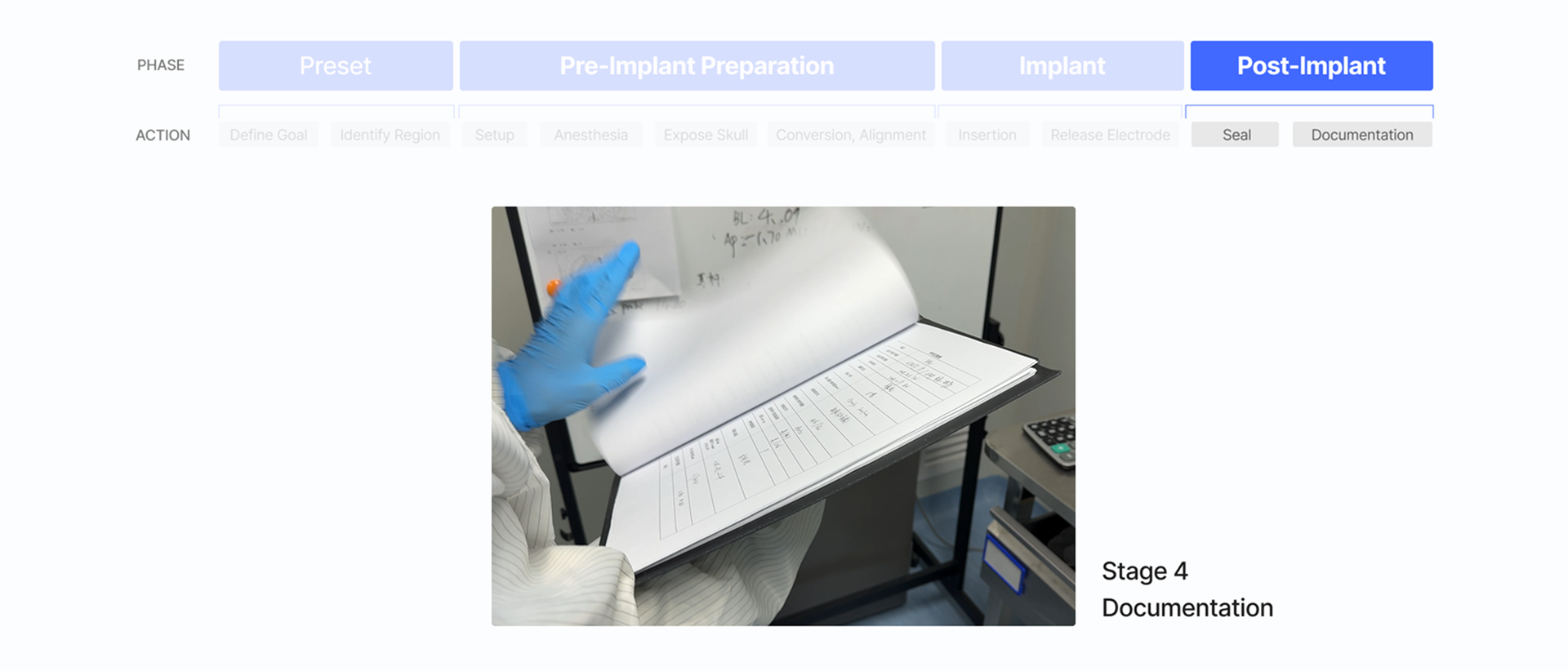

(We Observed 2 Surgeries on Site & Conducted 3 Interviews)Implantation Process

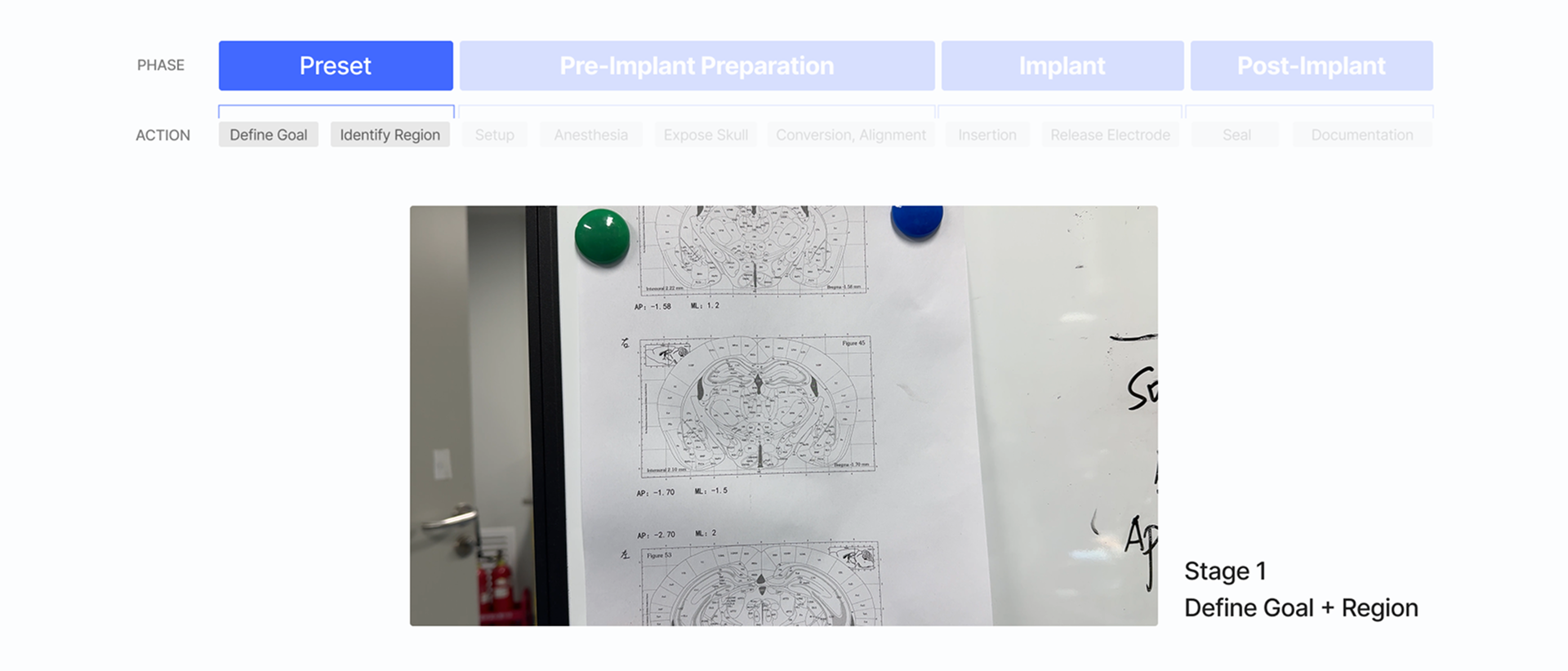

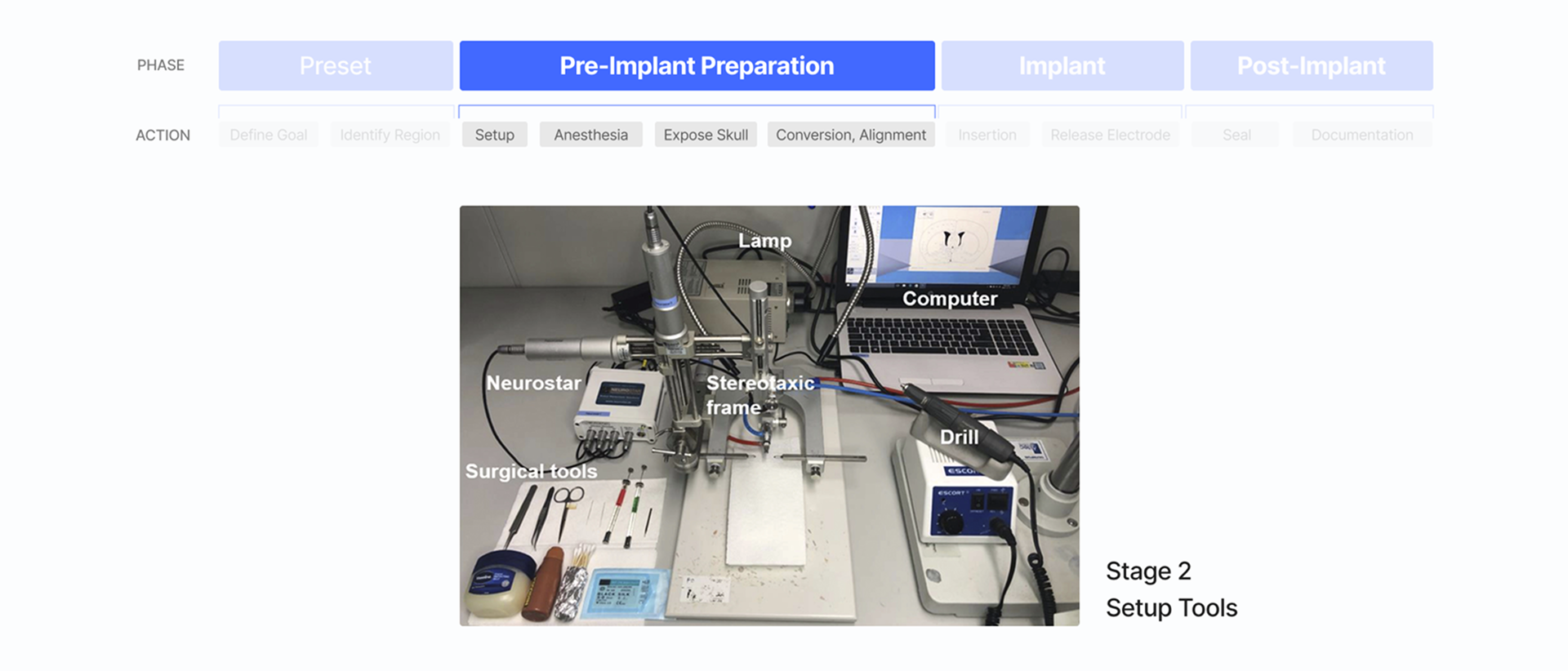

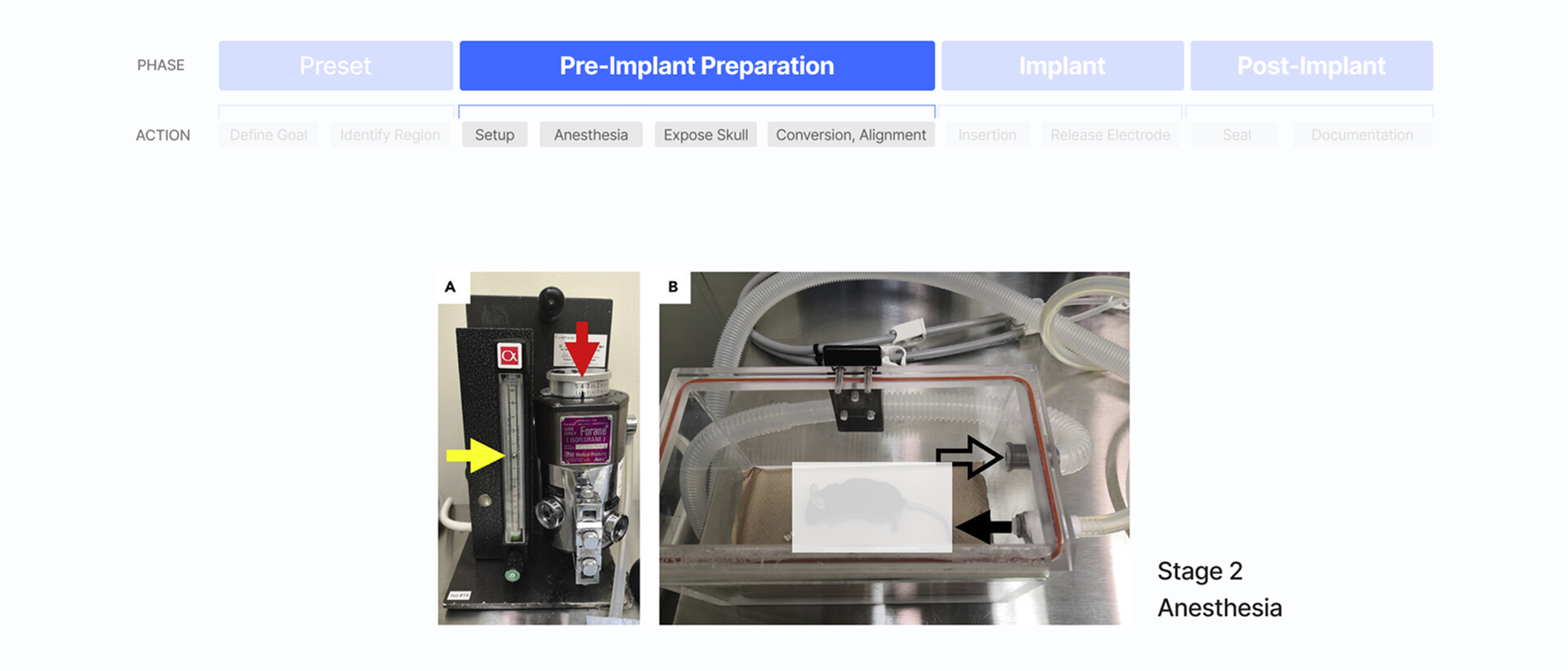

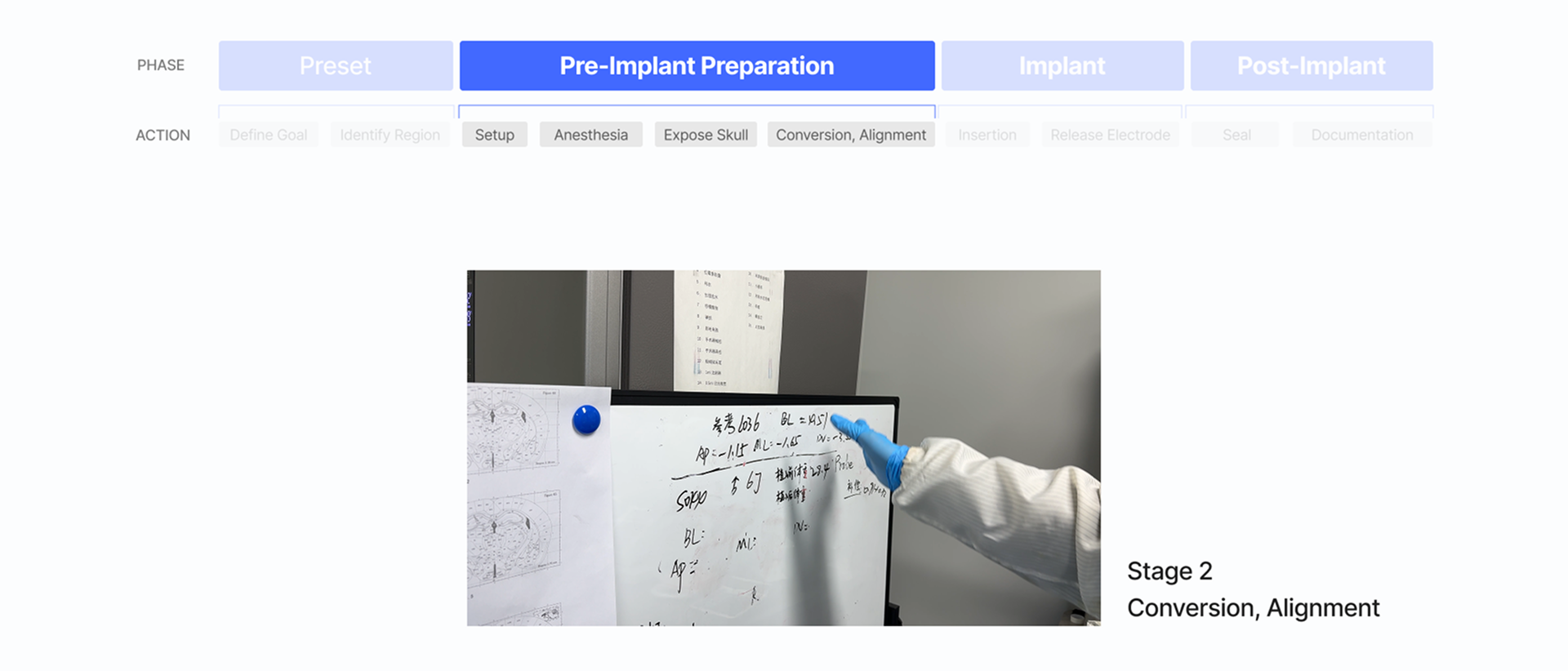

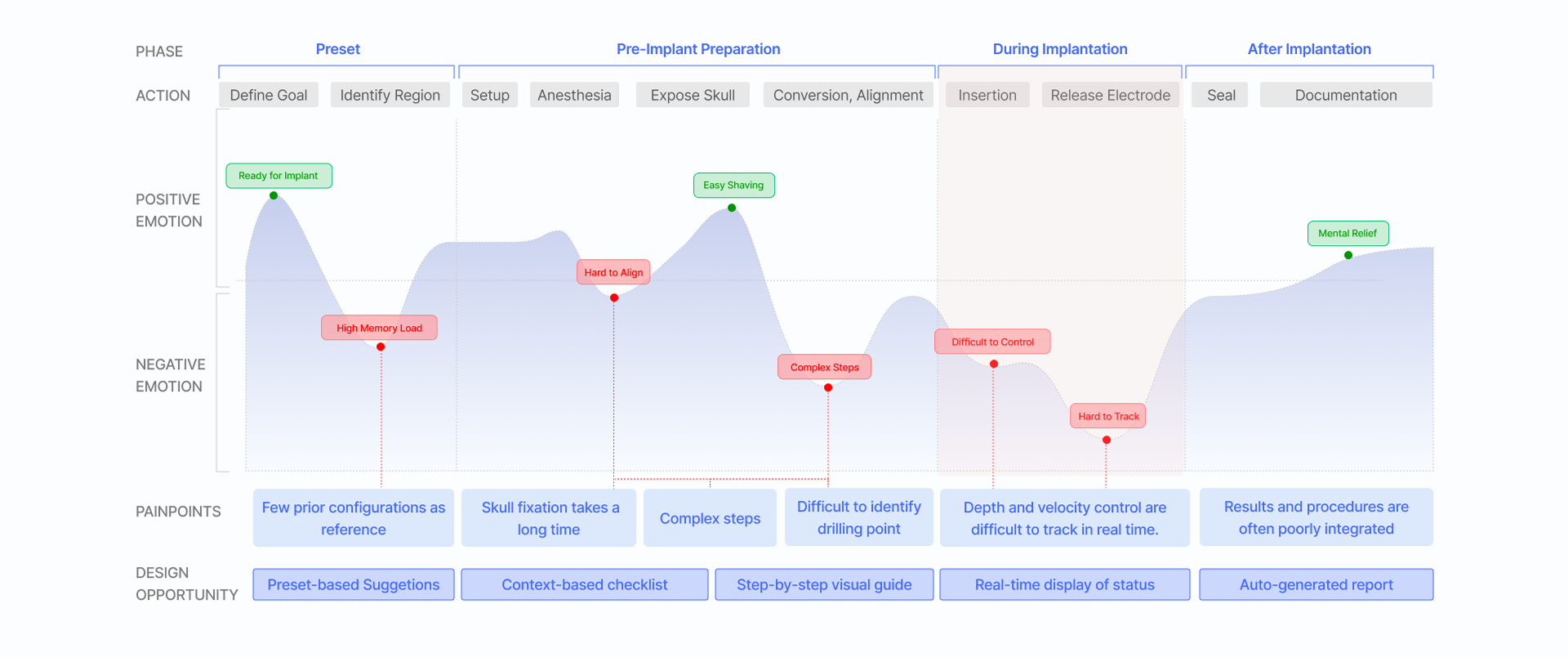

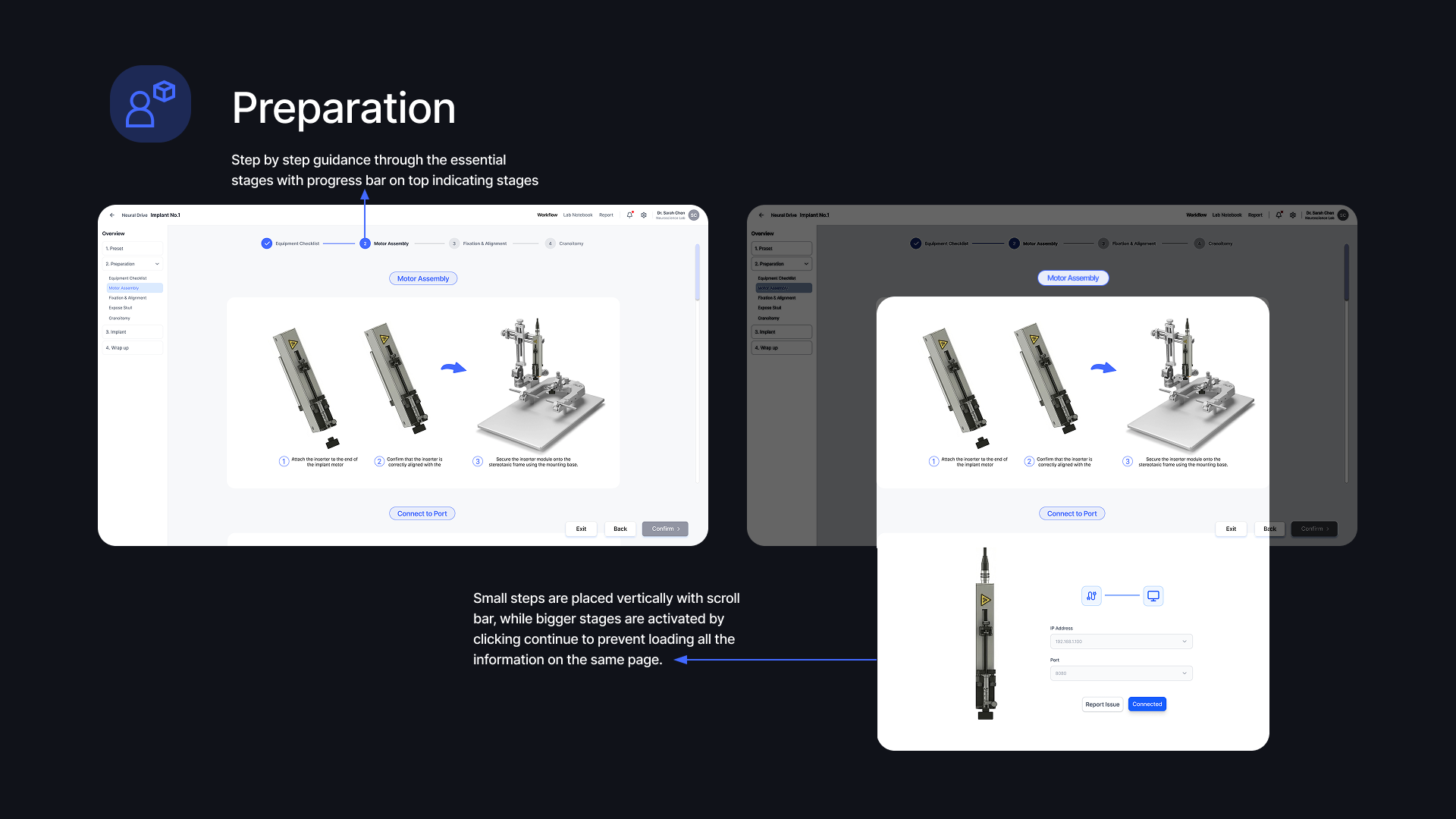

Mouse brain implantation is a multi-phase procedure involving more than 70 steps, from goal definition and preparation to insertion and post-implant documentation.

Each phase requires precise coordination between tools, software, and human judgment—making small mistakes costly and hard to detect.

What We Observed

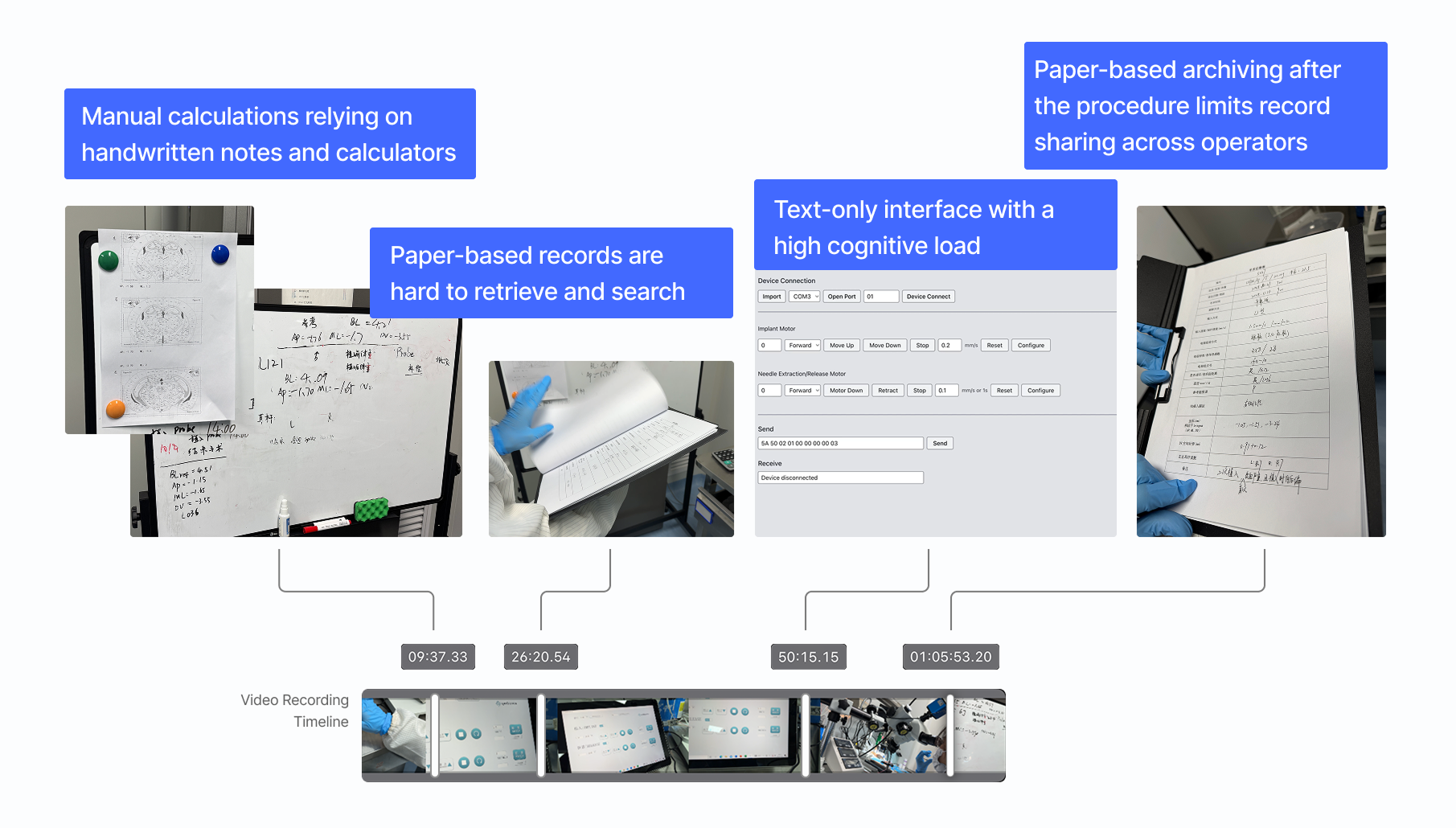

Across multiple procedures, we identified recurring friction points in the current workflow. These issues place heavy memory and attention demands on researchers, especially those with less experience.

Design Opportunities

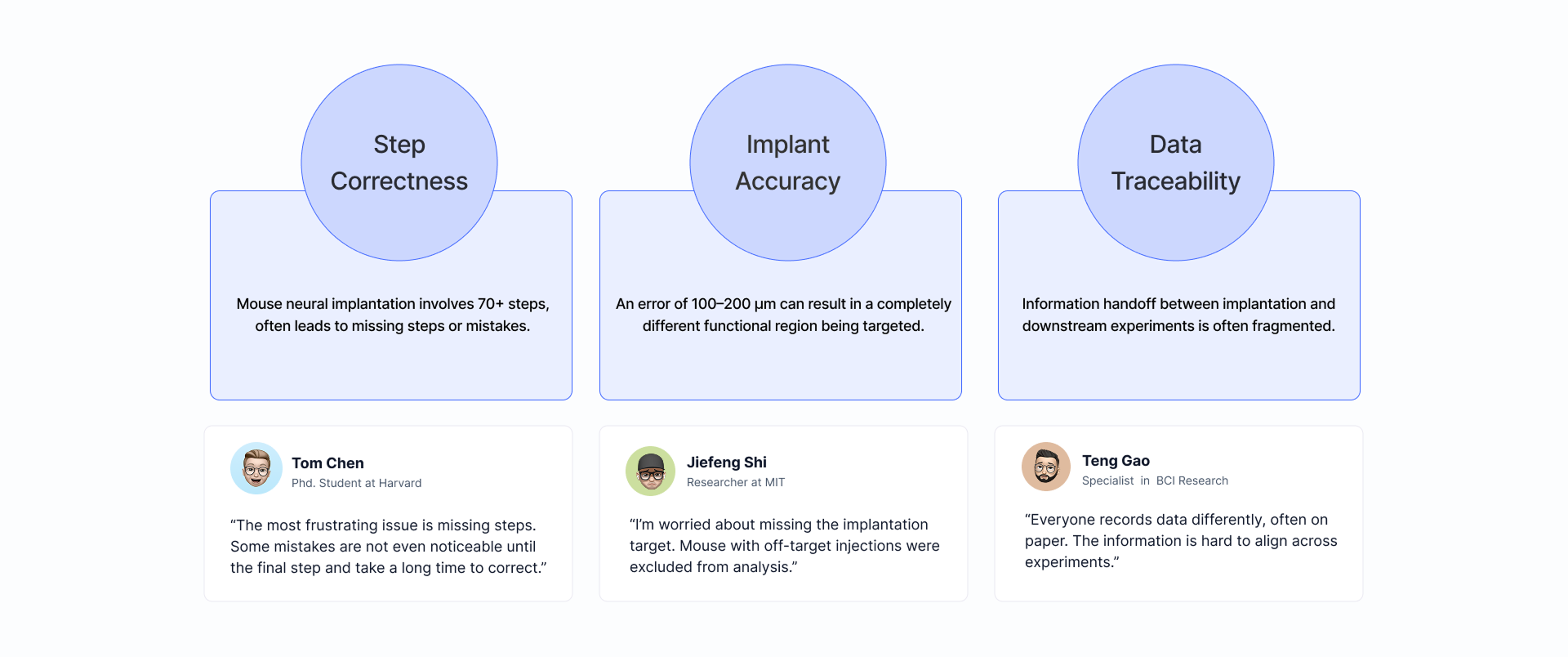

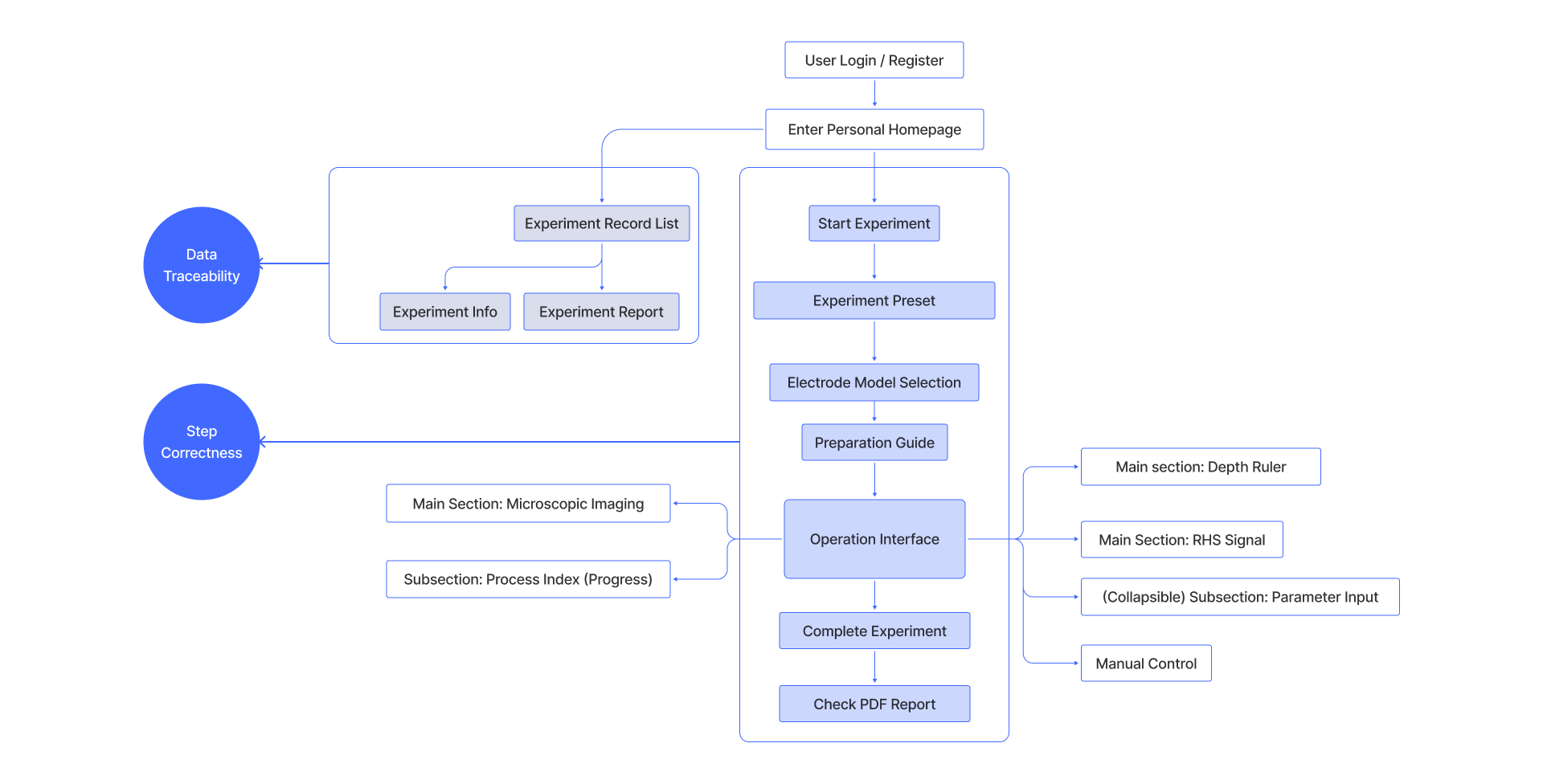

From these observations, we identified three core opportunities:

-

Step correctness — helping users avoid missing or incorrect steps

-

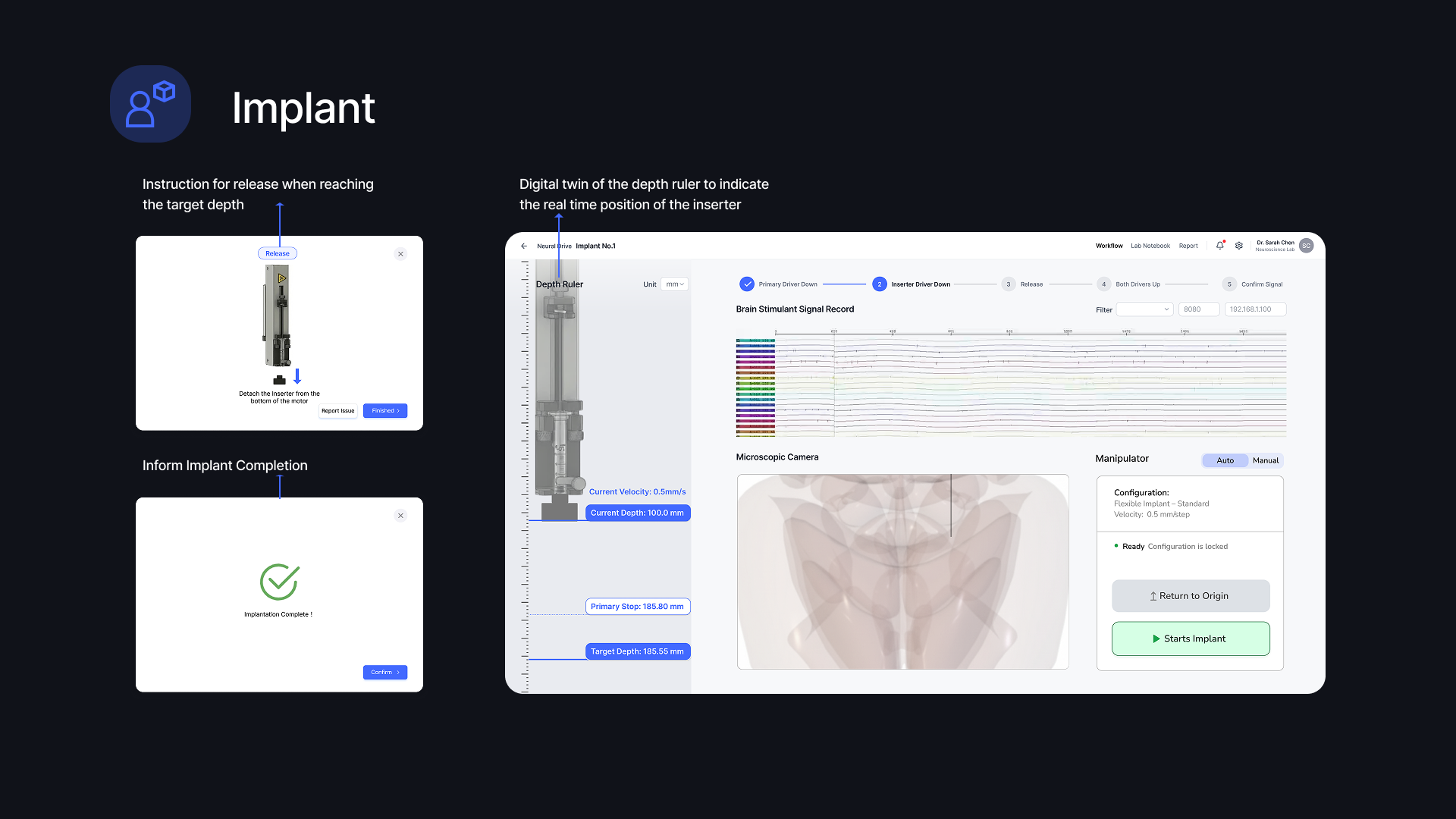

Implant accuracy — supporting precise depth and stage control

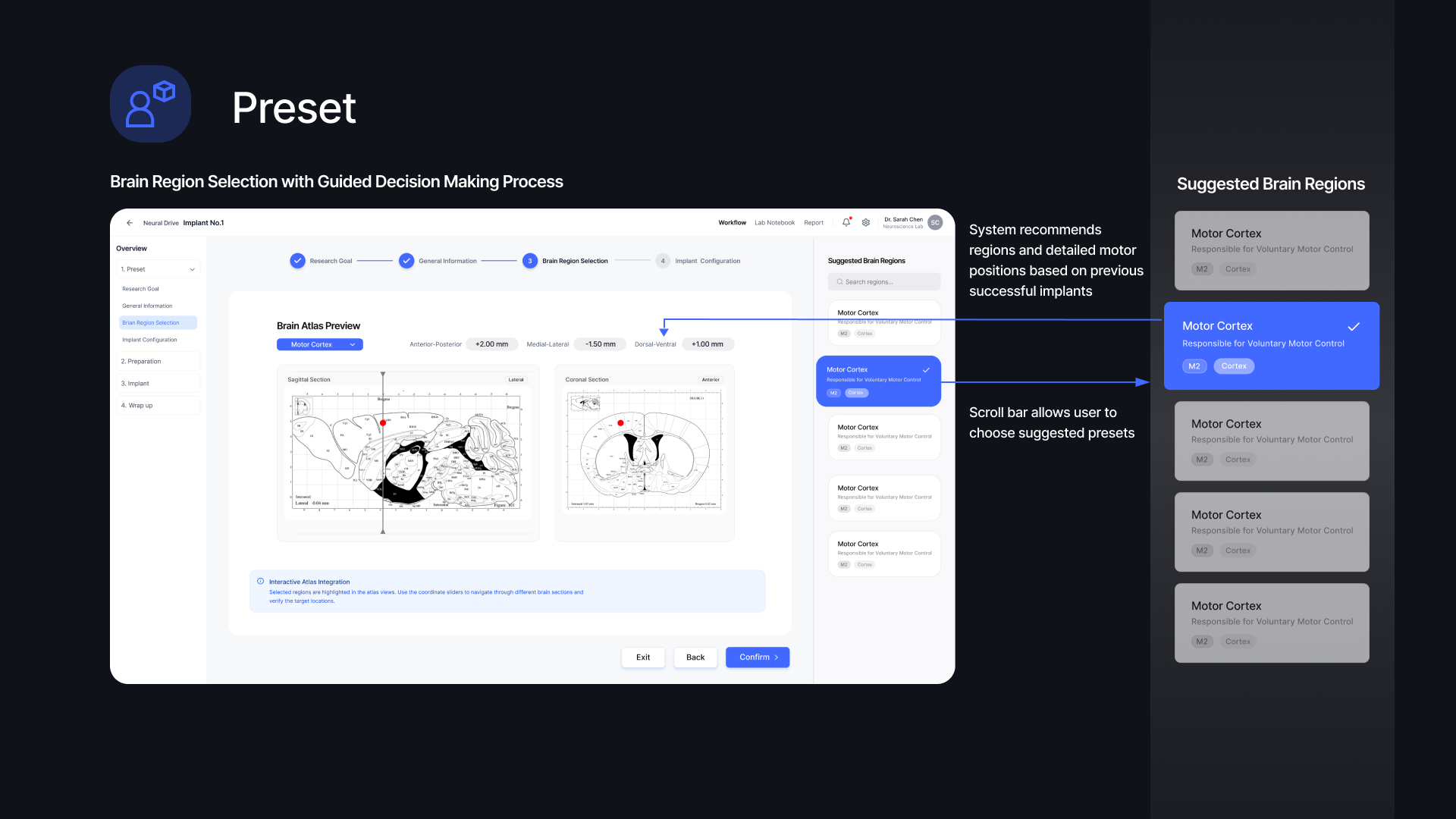

- Data traceability — making records consistent, searchable, and reusable

These opportunities guided all subsequent design decisions.

Through field observations and interviews, we identified three critical challenges that directly affect the reliability and scalability of mouse neural implantation.

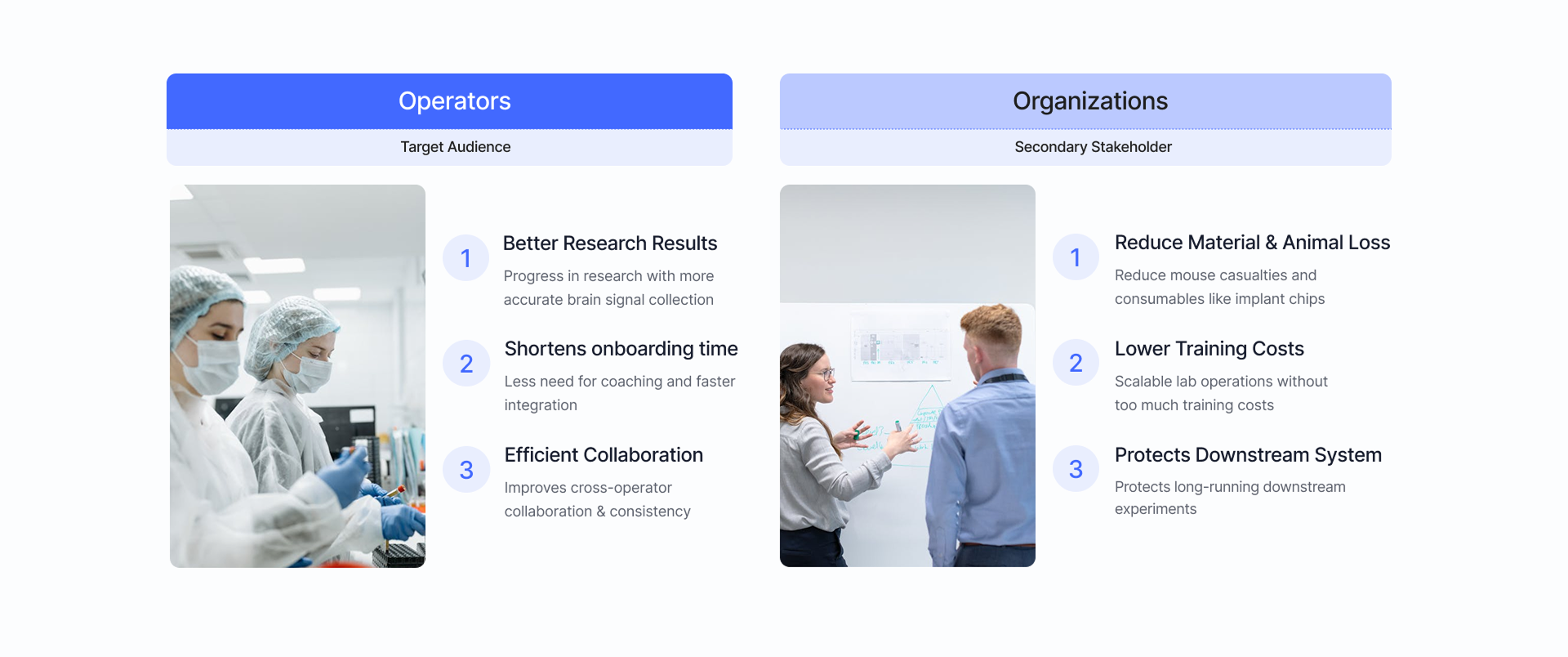

Improving implantation workflows creates value not only for individual operators, but also for research organizations operating at scale.

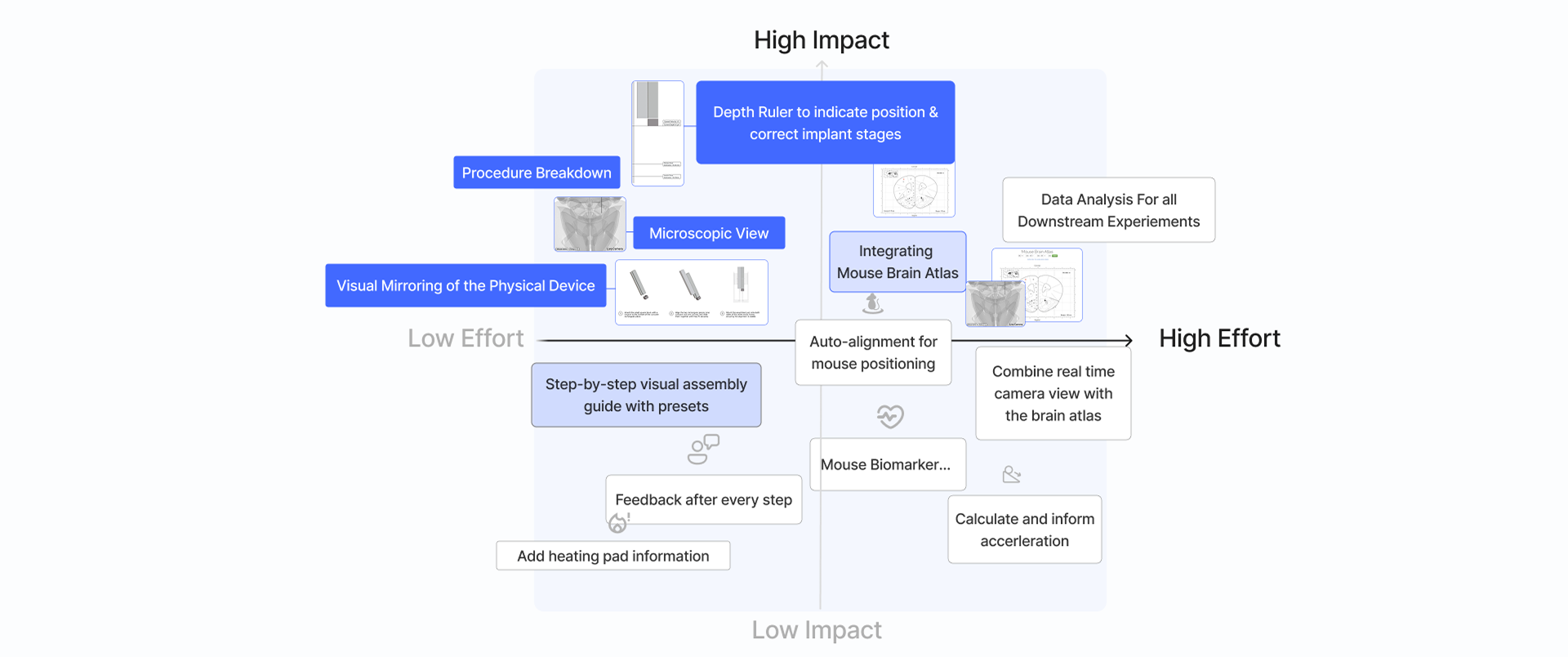

Feature Prioritization

To balance impact and development effort, we mapped potential features on an impact–effort matrix.

This helped us identify which ideas could most effectively improve implantation accuracy, step correctness, and data traceability—while remaining feasible within the project scope.

MVP & Lo-fi Design

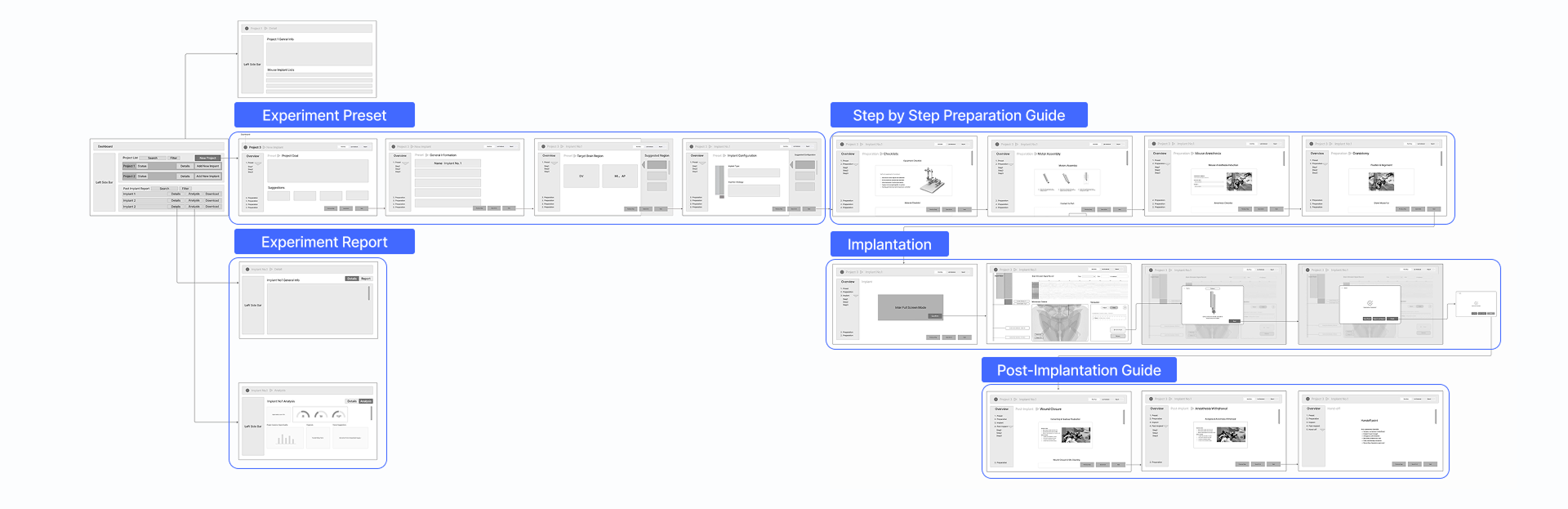

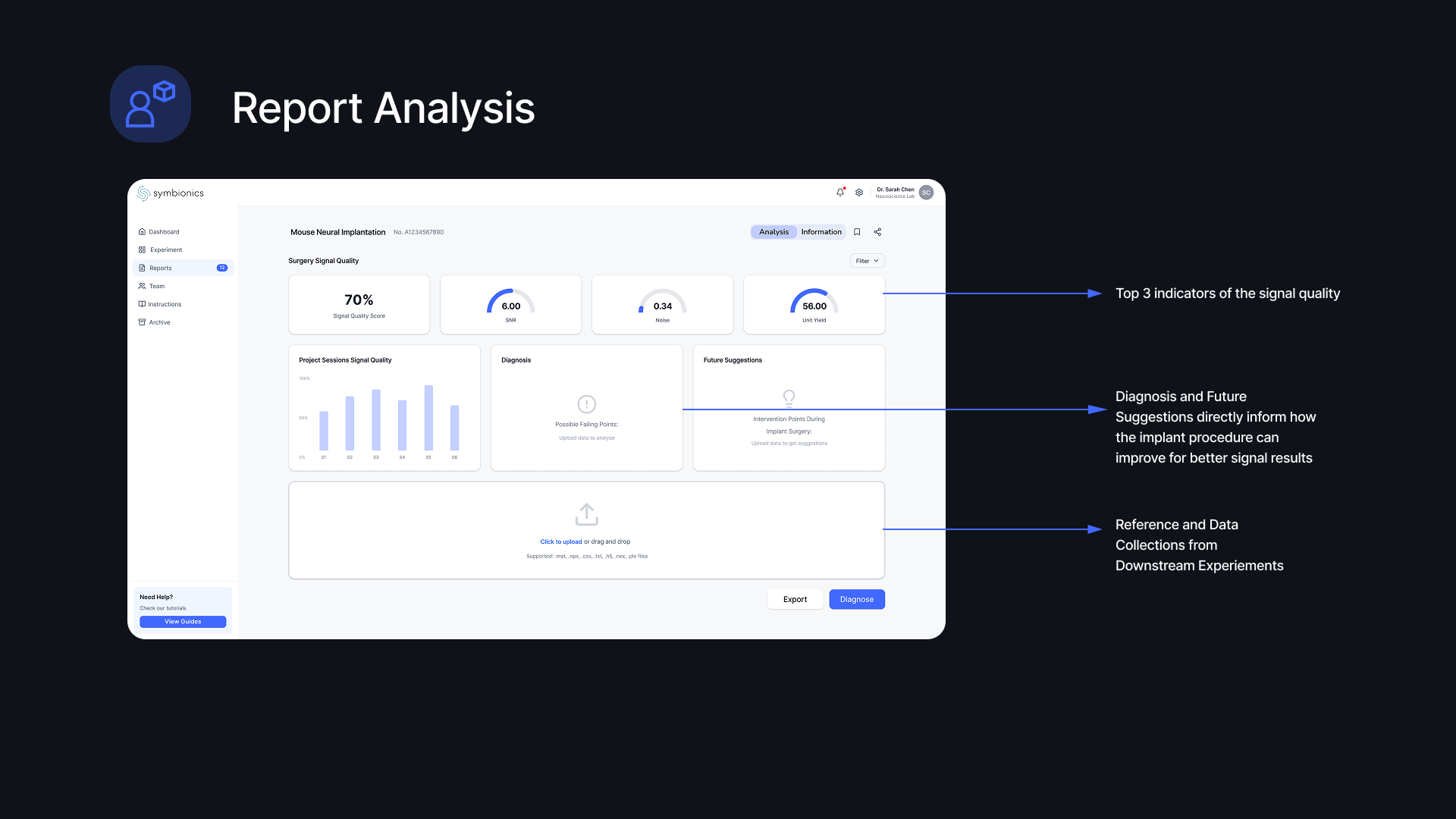

We then focused on building a guided workflow that supports users before, during, and after implantation.Key concepts include presets, step-by-step guidance, real-time status feedback, and auto-generated reports.

Usability Testing

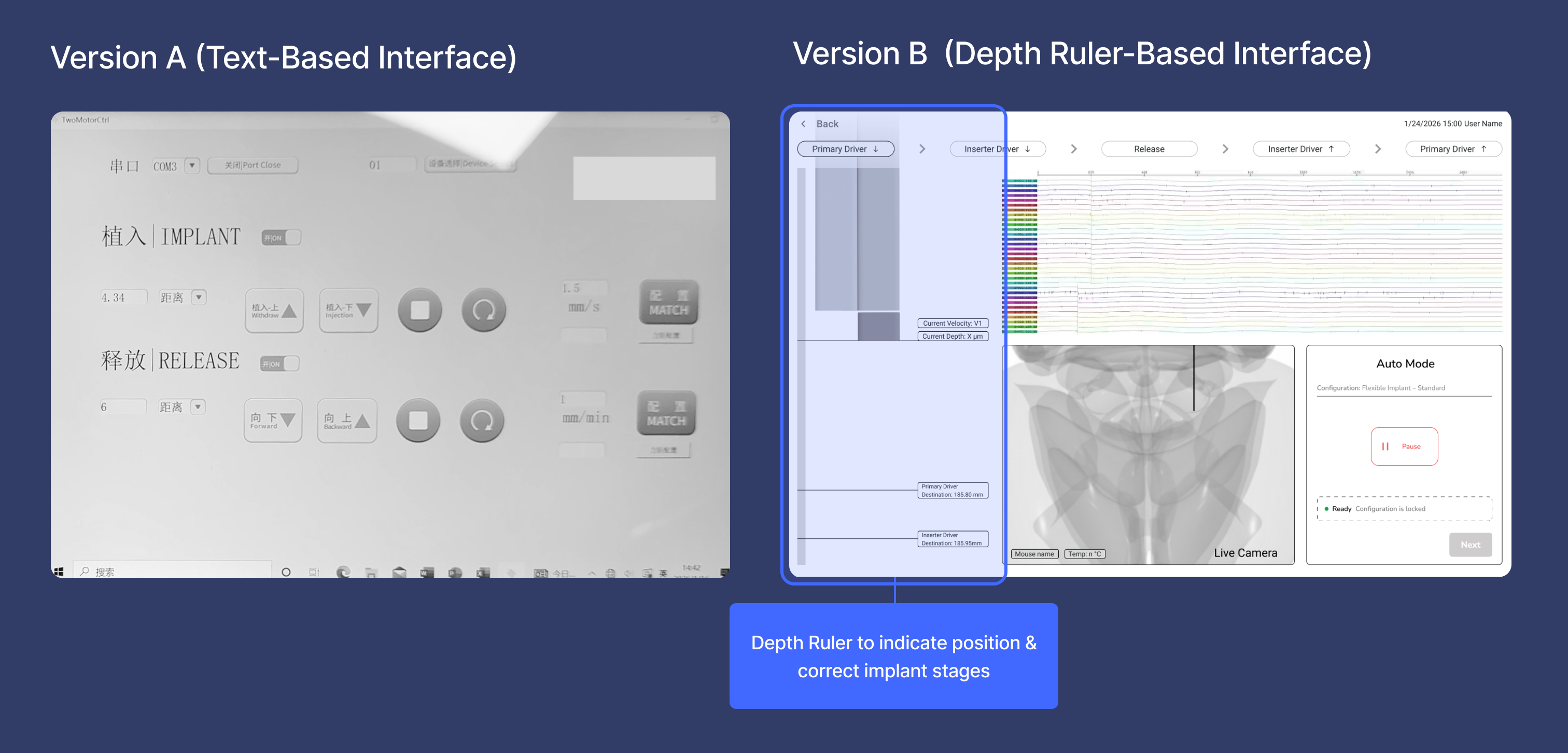

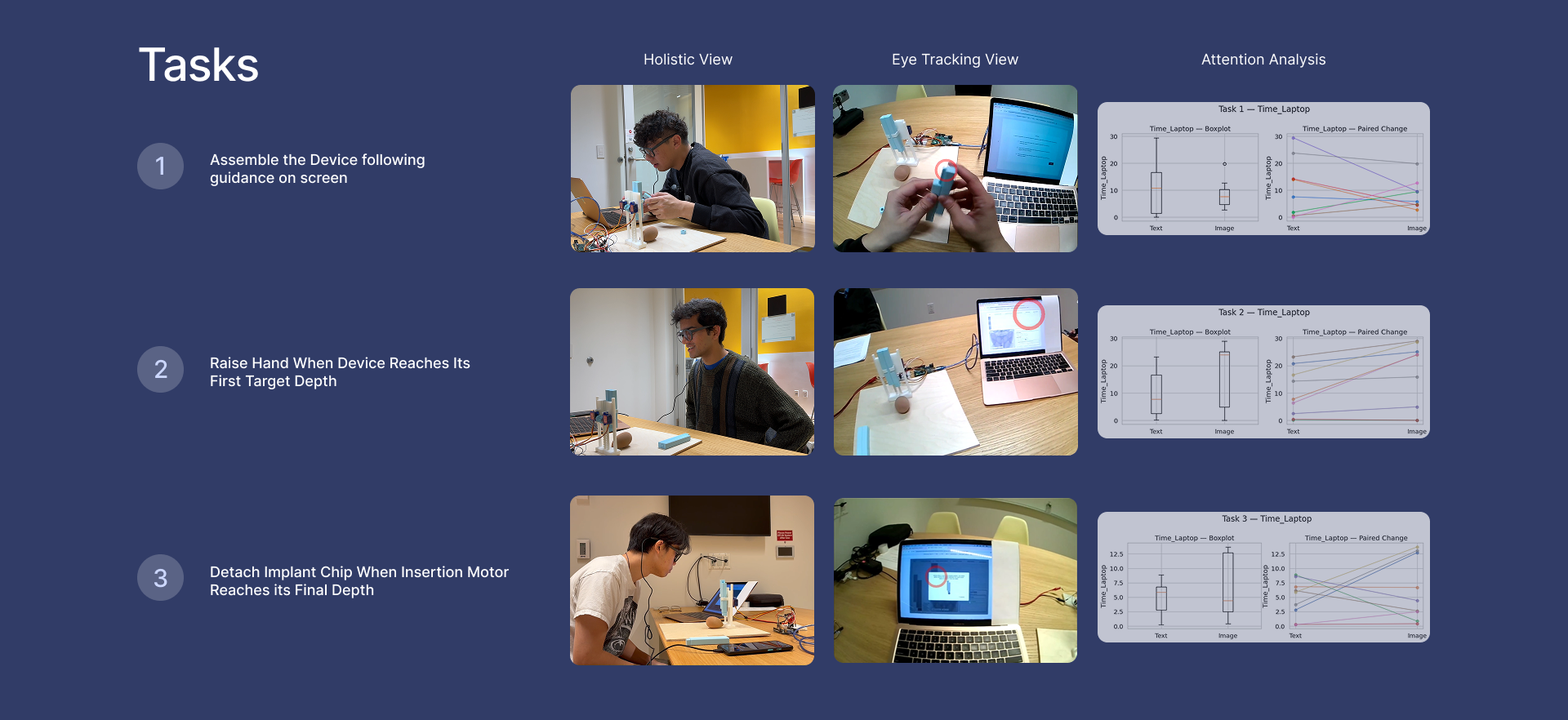

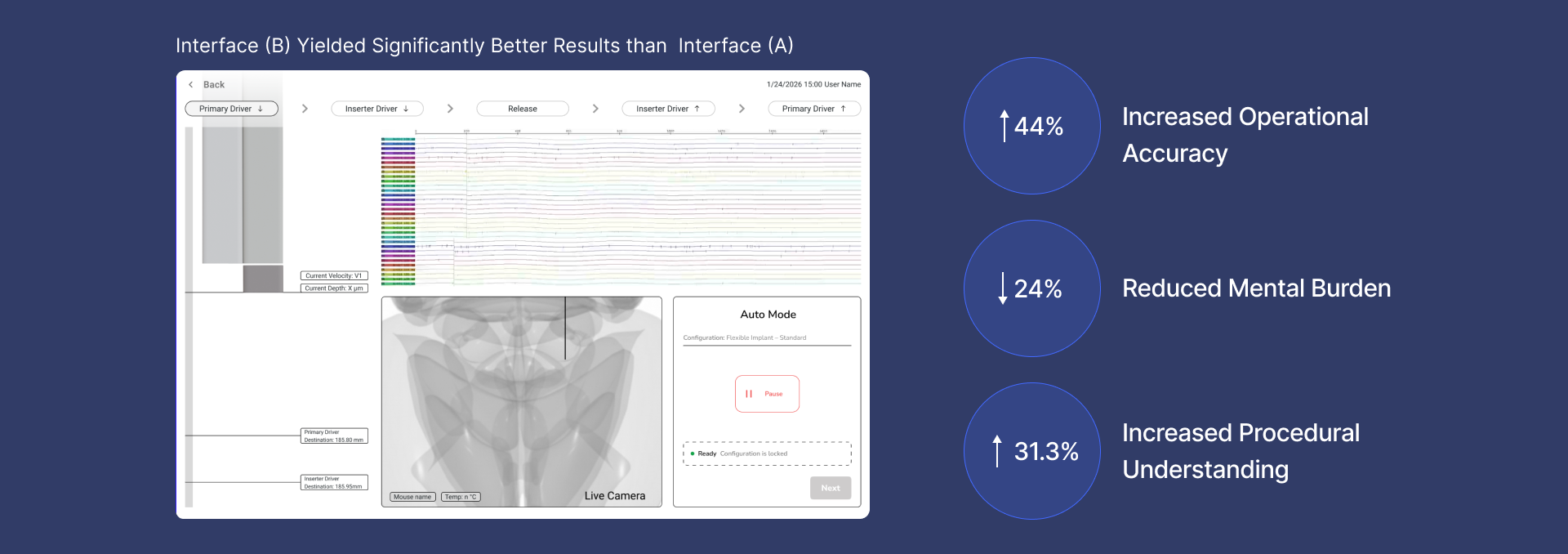

We evaluated the design through an A/B usability test with 9 novice researchers from Harvard graduate programs. Participants completed the same tasks using two interfaces: the original text based interface and a depth ruler based interface.

Success Metrics

To evaluate whether the design meaningfully improved the implantation workflow, we defined clear success metrics focused on task performance and reliability. This category measures how accurately and consistently users complete implantation tasks during testing.

Task completion rate target: At least 90% of participants complete all required tasks without abandoning the workflow.

Operational accuracy target:

Achieve ≥ 75% overall accuracy in target depth and implantation stage alignment.

Critical error frequency target: No more than one critical error per participant per session during key procedural steps.

Test Setup

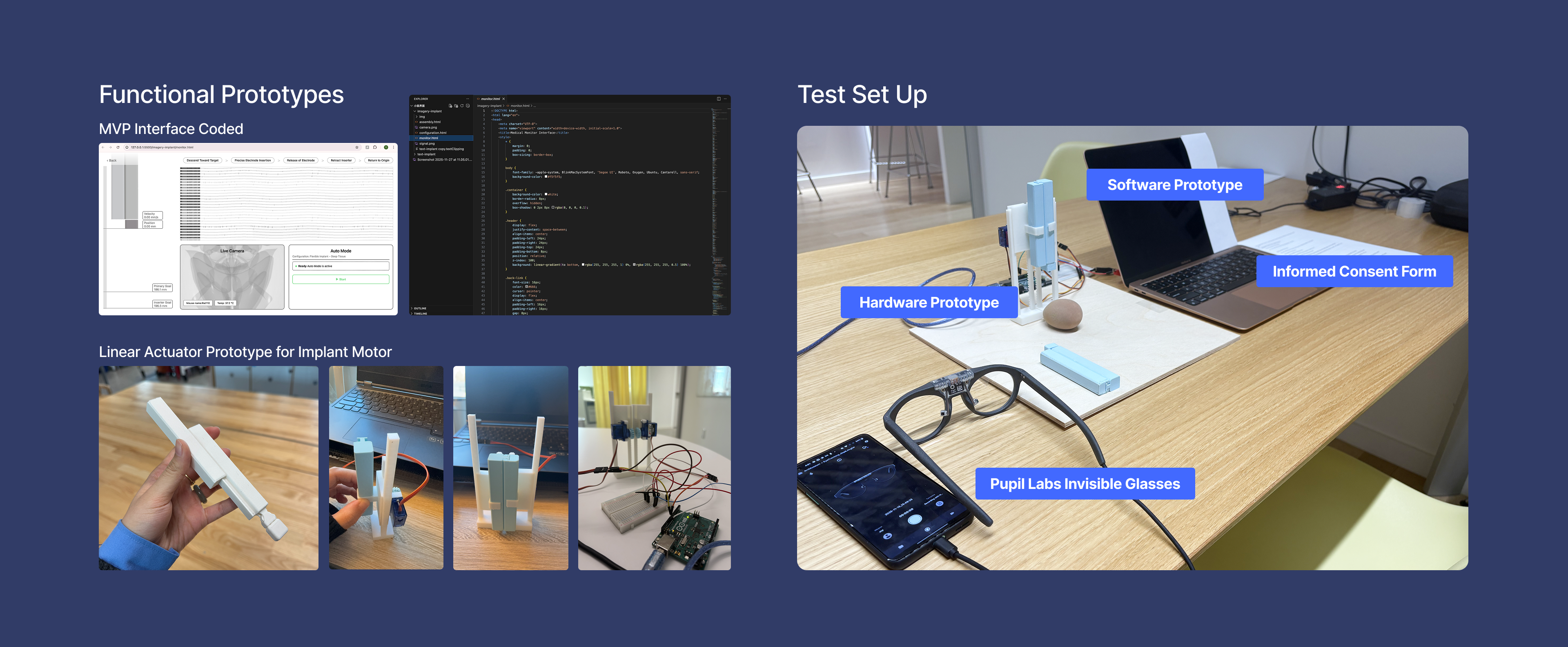

To validate the design in realistic conditions, we built functional software and hardware prototypes and integrated them into a single test setup. The goal was not production readiness, but speed, controllability, and experimental fidelity.

Software Prototype

The MVP interface was fully coded by HTML/CSS/Javascript to support real task execution during usability testing. This mid-fi prototype prioritized clarity and responsiveness to support novice users under time pressure. It enabled participants to interact with the system as they would in a real implantation workflow.

Hardware Prototype

To simulate the physical behavior of the implantation system, we built a linear actuator prototype for the implant motor. We connected hardware inputs directly to the software interface, allowed precise control of movement and depth during tasks. This setup ensured that software decisions were grounded in physical interaction, not abstract simulations.

Results Overview

By making system state and procedural progress visible at a glance, the redesigned interface reduced guesswork and supported more confident decision-making during implantation.

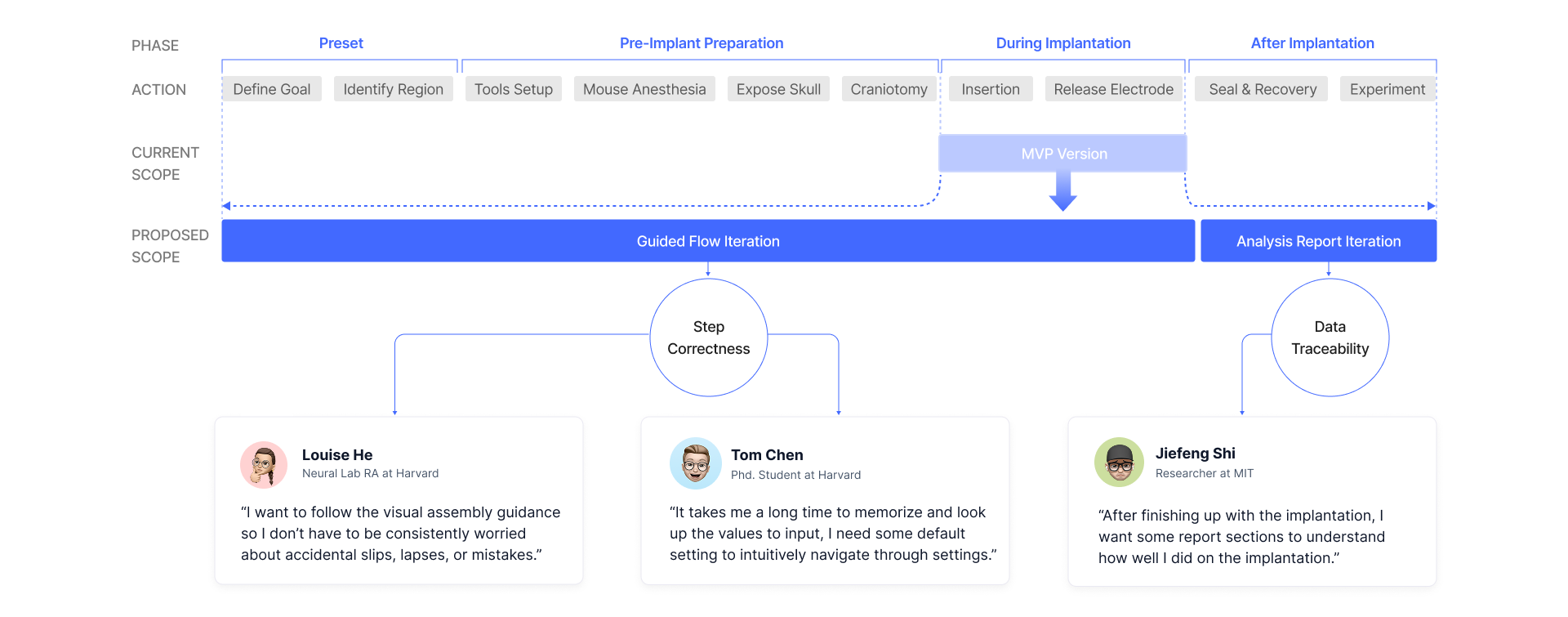

Proposed Scope Expansion

The implantation process spans multiple phases, from goal definition and preparation to execution and post-implant analysis.Our initial MVP focused on the most error-prone and cognitively demanding phase—the implantation itself—where usability issues have the greatest impact on outcomes.Following usability testing, we conducted post-test interviews and surveys to better understand user behavior, mental load, and unmet needs across the broader workflow.Insights from these qualitative and quantitative findings informed how we defined the next areas for expansion.

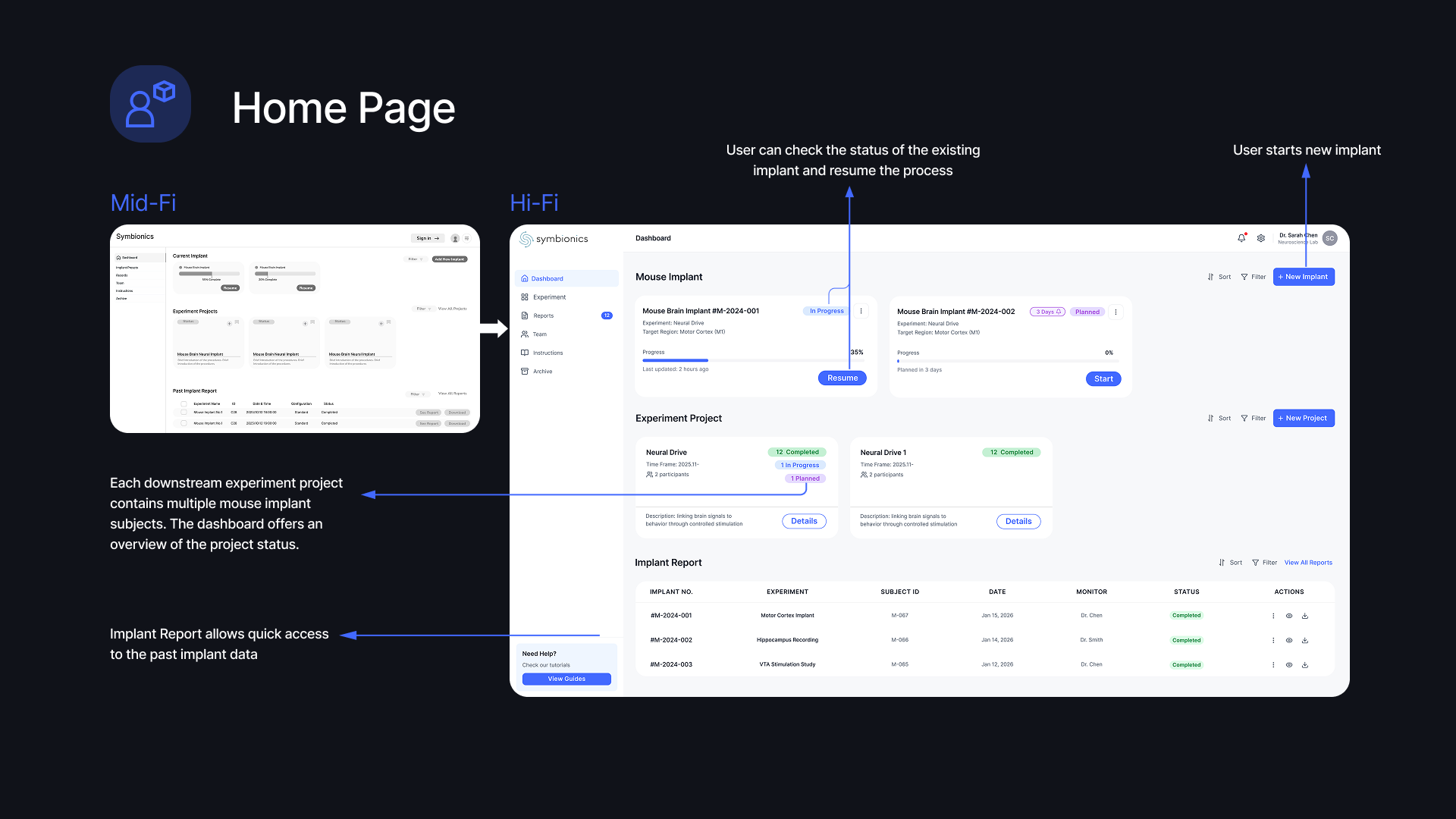

Hi-fi Design

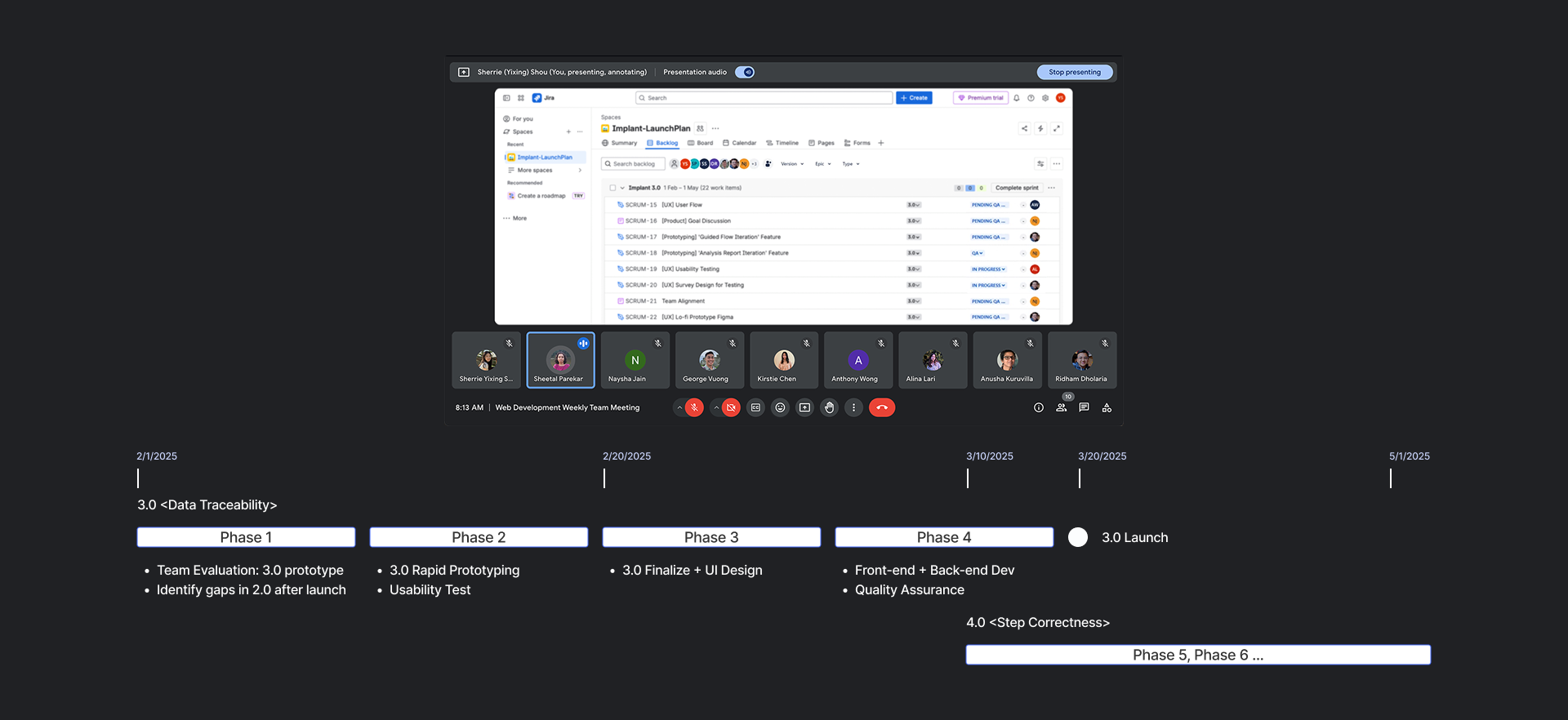

Launch Plan

To move the design from concept to production, we collaborated with cross-functional teams to define a phased launch plan.The roadmap aligns design, engineering, and testing efforts, ensuring that each release is validated before moving to the next stage.This phased approach allows the team to ship incrementally, incorporate real user feedback, and reduce risk in a high-stakes research environment.